Instrumentation cables are designed to maintain the integrity of the signals they carry by incorporating various features and techniques that minimize interference and ensure the accuracy and reliability of the transmitted data. Here are some ways in which these cables achieve signal integrity:

Twisted Pairs or Triads: Many instrumentation cables consist of twisted pairs or triads of conductors. The twisting of the conductors is a key technique to cancel out electromagnetic interference (EMI) and radio-frequency interference (RFI). When the conductors are twisted together, any electromagnetic fields or interference affecting one conductor will also affect its paired conductor in the same way but in the opposite direction. This results in mutual cancellation, reducing the impact of external interference on the signals.

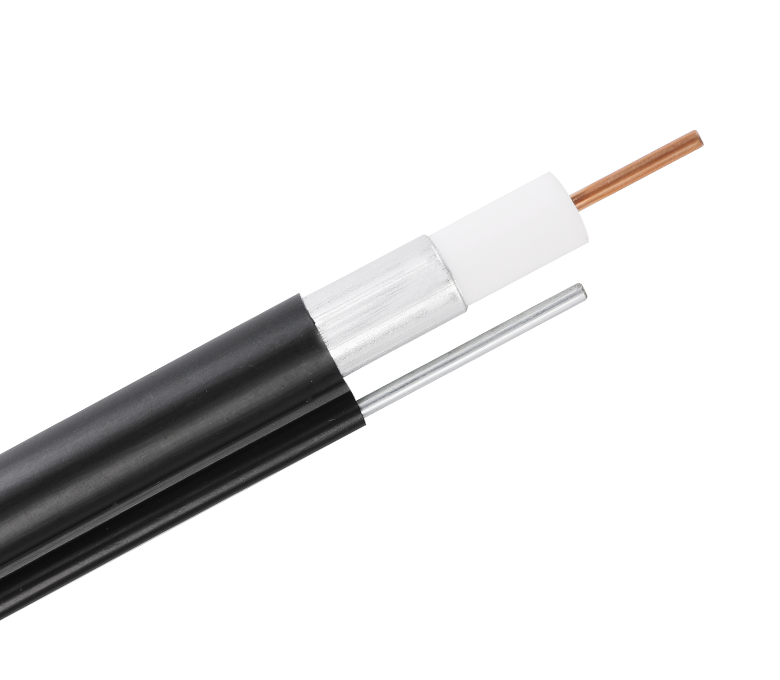

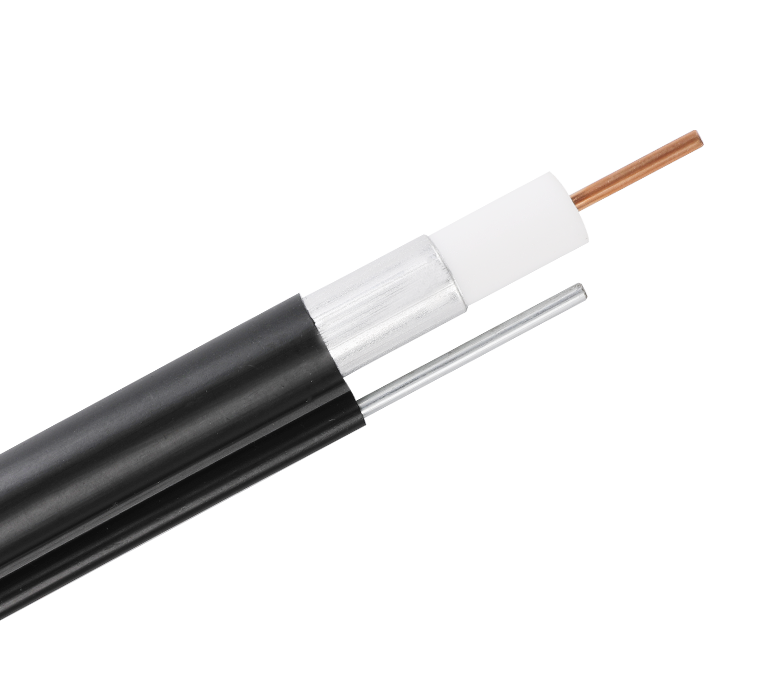

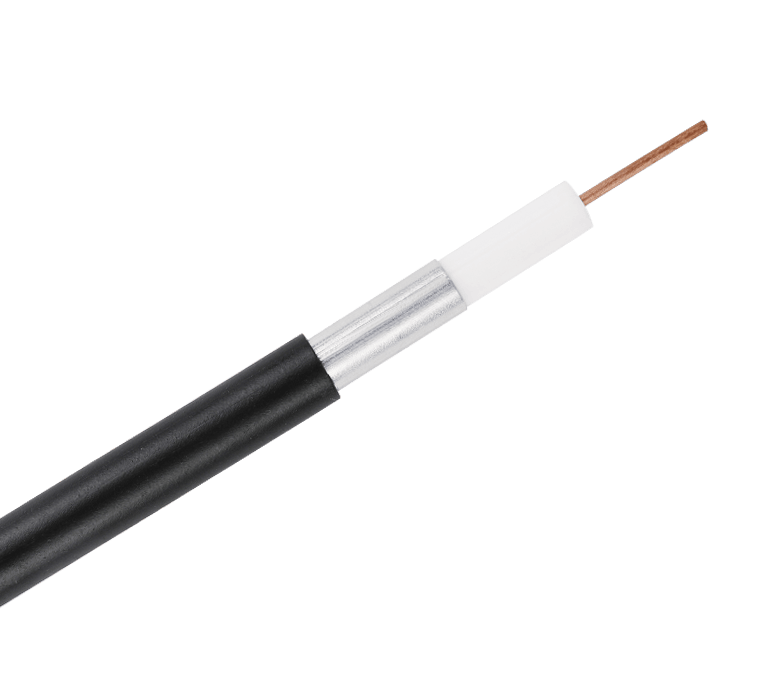

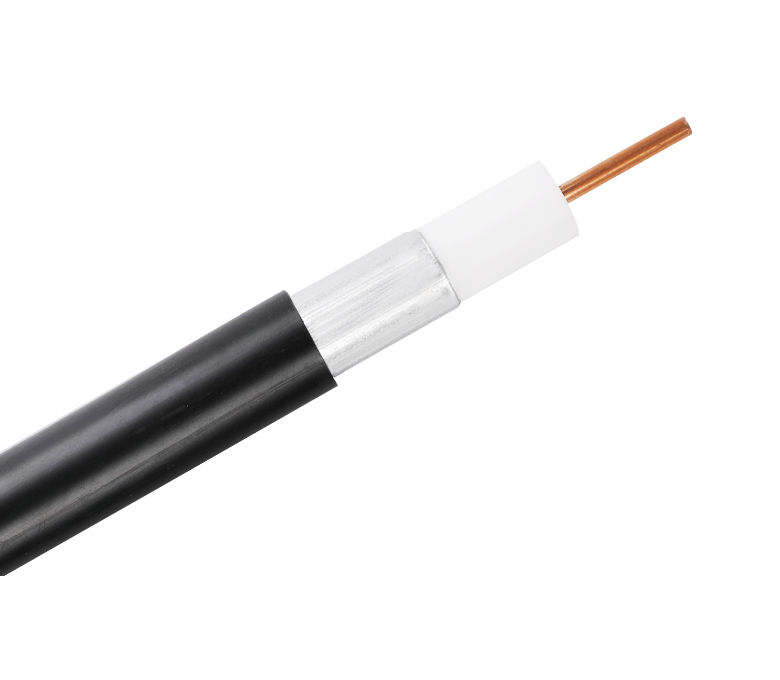

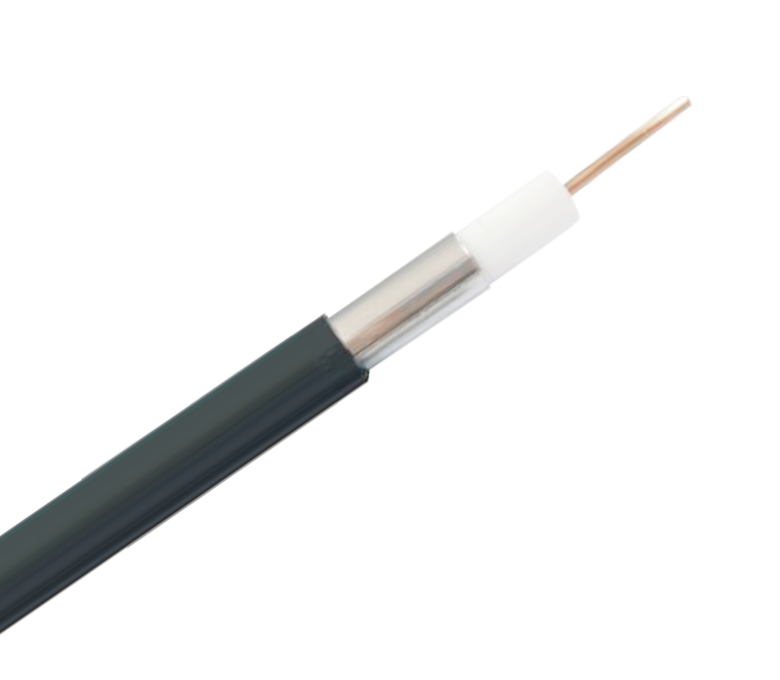

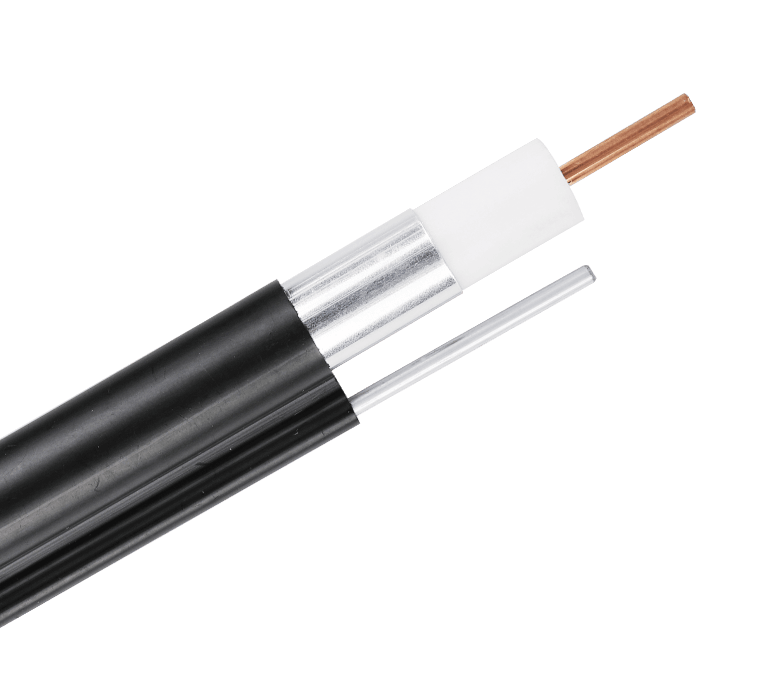

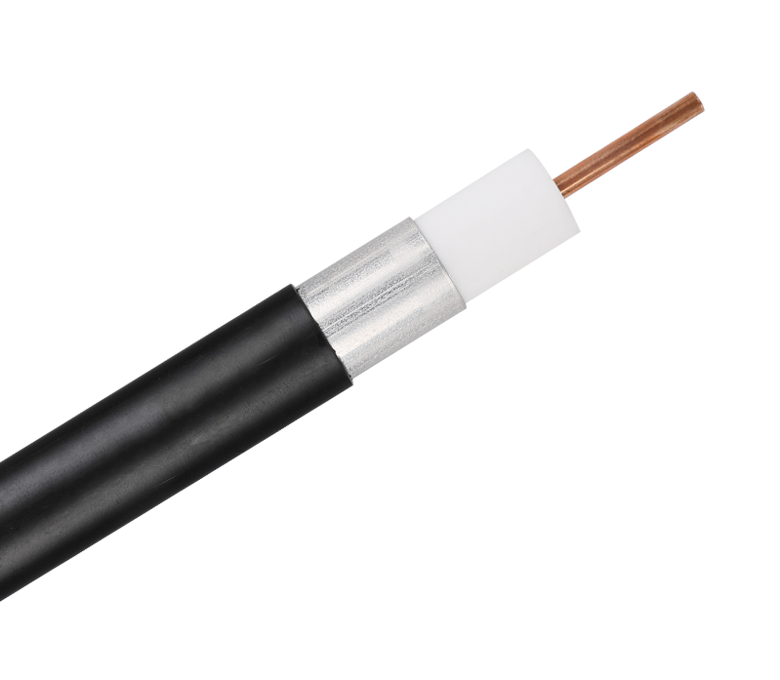

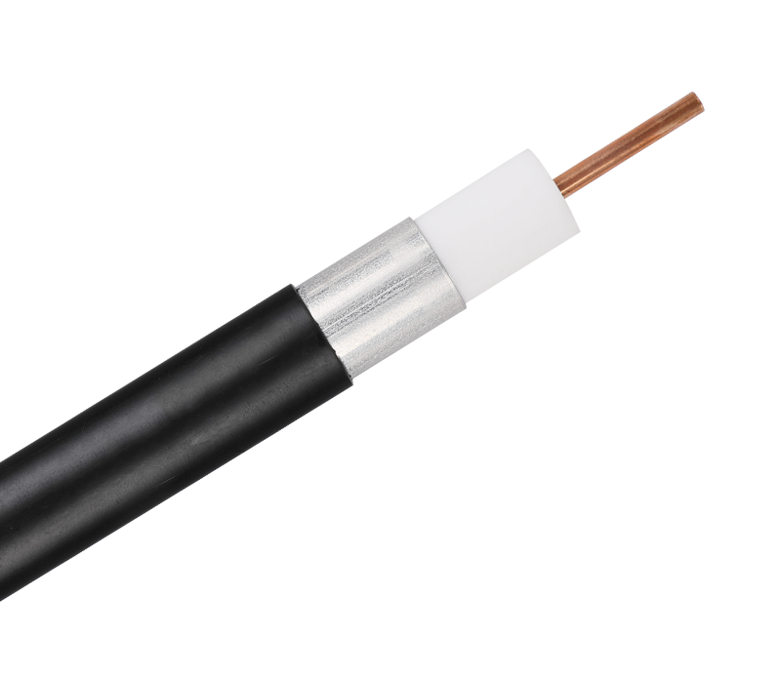

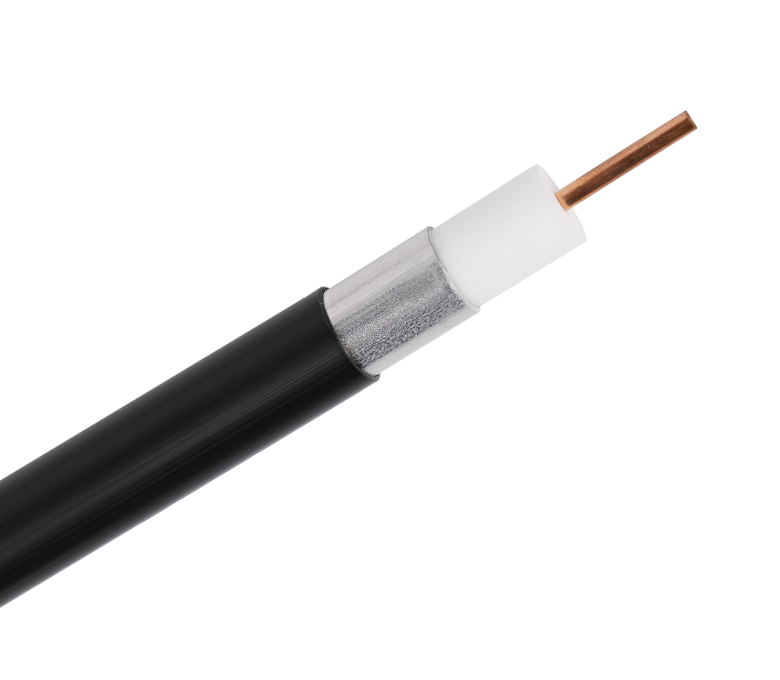

Shielding: Instrumentation cables often include shielding to protect against external interference. Shielding can be in the form of individual conductor shields, an overall shielding layer, or both. Shields are typically made of materials like foil or braided metal, which provide a barrier against EMI and RFI. By grounding the shielding, any interference that penetrates the cable is safely conducted away from the conductors, preserving signal integrity.

Quality Insulation: The insulation material surrounding the conductors is carefully selected to provide high dielectric strength, protecting the conductors from each other and from the cable's outer environment. High-quality insulation materials maintain the separation of conductors, preventing signal leakage and cross-talk.

Low Capacitance: Instrumentation cables are designed to have low capacitance, which minimizes the delay and distortion of electrical signals. Low capacitance cables are well-suited for transmitting high-frequency signals accurately.

Balanced Impedance: The impedance of instrumentation cables is balanced to ensure that the electrical characteristics of the two conductors in a twisted pair or triad are similar. This balance is crucial for preventing common-mode noise, where both conductors are affected equally by interference, which can be canceled out by the receiving equipment.

High-Quality Materials: The materials used in the construction of instrumentation cables are of high quality, chosen for their electrical properties and ability to withstand environmental factors. This includes selecting materials that resist moisture, heat, and chemicals to maintain the cables' performance over time.

Grounding: Proper grounding of the cable shields and conductors is essential to mitigate any potential differences in electrical potential that could introduce interference. Grounding ensures that any induced voltage from external sources is safely conducted away from the cable.

Compliance with Standards: Instrumentation cables are often manufactured according to industry standards and specifications that define the requirements for signal integrity. Adhering to these standards helps ensure the cables meet specific performance criteria.

By incorporating these design and engineering features, instrumentation cables are able to maintain the integrity of the signals they carry, even in electrically noisy environments. This is critical for applications in process control, automation, and data transmission, where accurate and reliable data transfer is essential for system performance and safety.

浙公网安备33018502001191号

浙公网安备33018502001191号