The main function of optical cable is optical signal transmission, which can meet the specifications of optical, mechanical, and environmental performance. It is made of optical fiber, a plastic sheath, and a plastic outer layer. It is a kind of communication road for optical signal transmission. Below, Optical Fiber Cable Factory introduces the selection requirements of optical fiber cables:

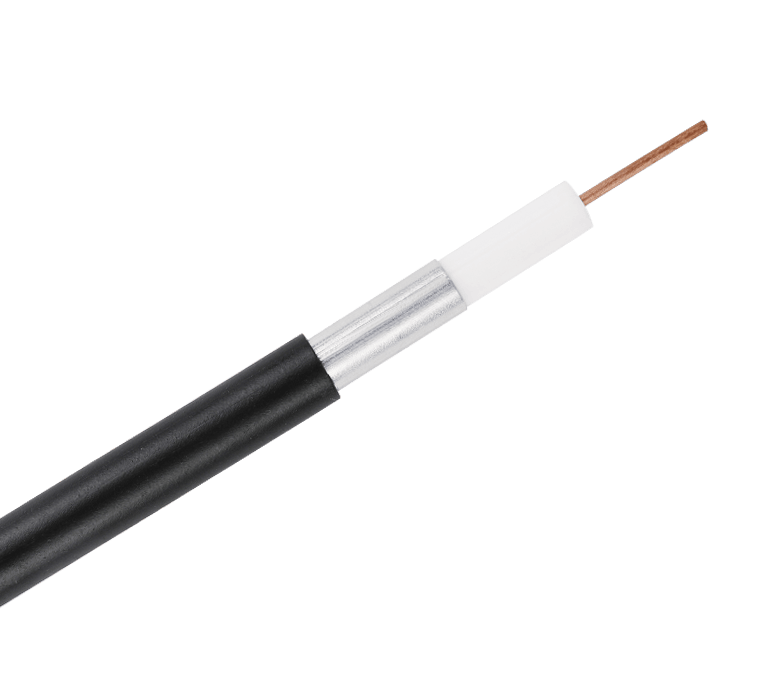

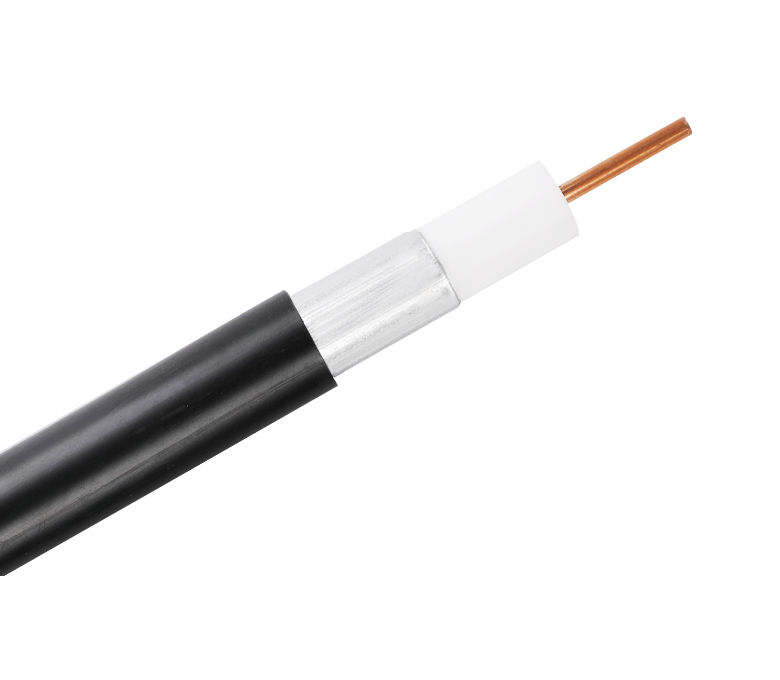

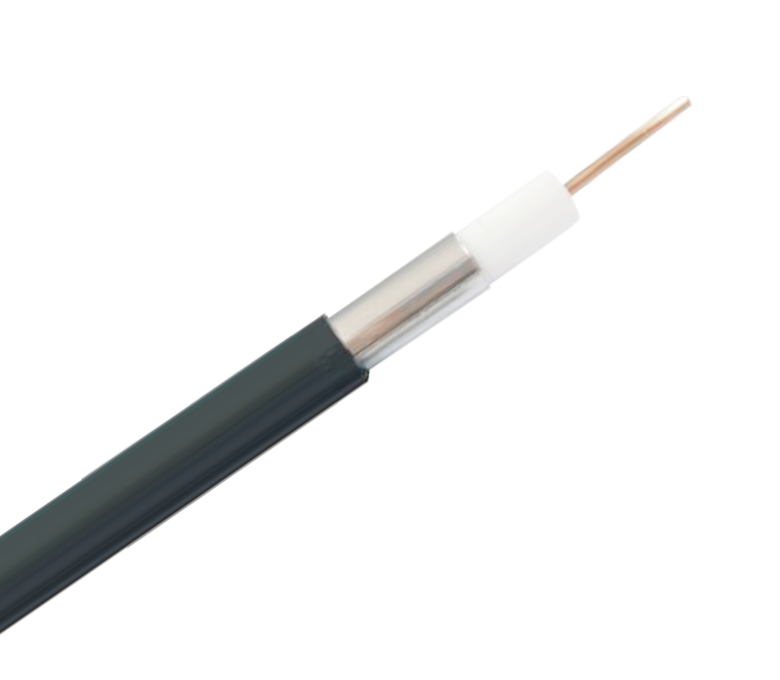

1. From the perspective of the outer skin, the outer skin of normal high-quality optical cables is made of polyvinyl chloride material, which looks smooth and shiny, has excellent flexibility and has a flame retardant effect. Connecting a poor-quality jacket means that it is of poor quality. This type of optical cable is of poor material, and it will crack and seep water after a long time of use, which is very dangerous.

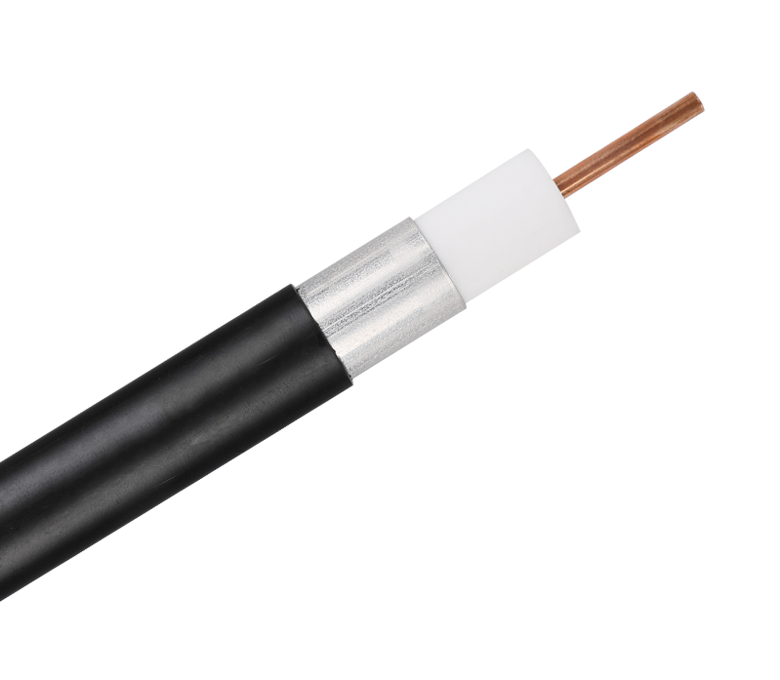

2. From the perspective of optical fibers, the optical fibers of high-quality optical cables are usually graded cores, while the inferior ones are grades c and d, which will cause the transmission distance to be too short, and there is no way to connect with pigtails.

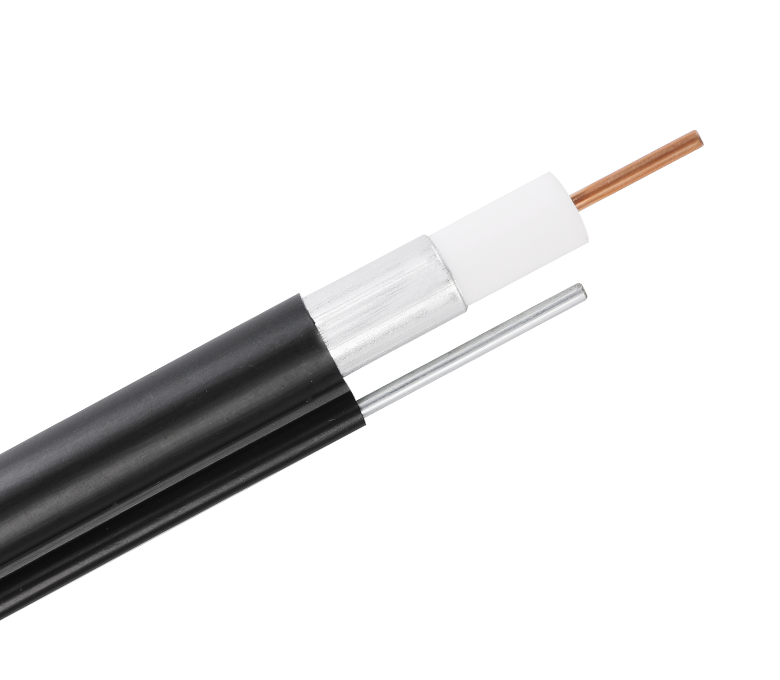

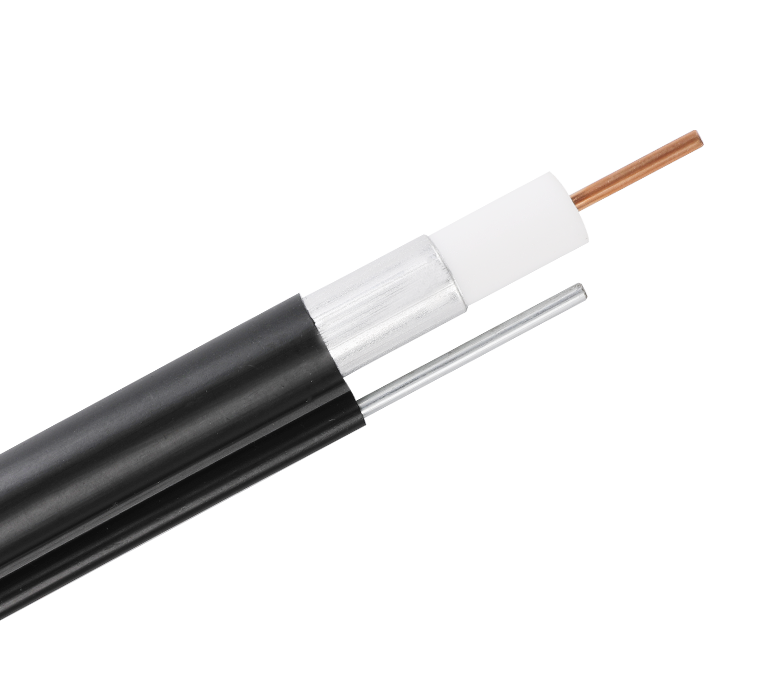

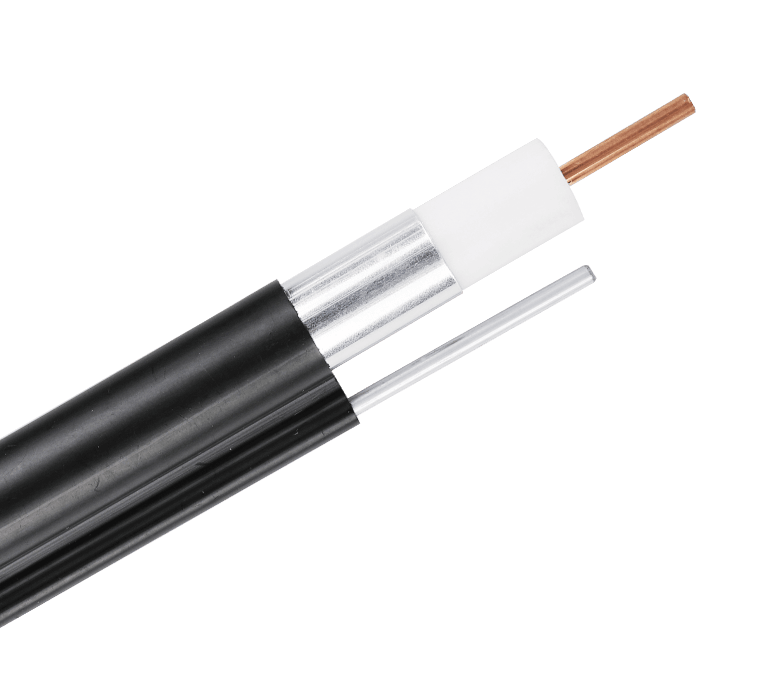

3. When purchasing an optical cable, make sure that the steel wire meets the standards. Normally, its steel wire must be specially treated, which can reduce the probability of rusting and improve its strength. The steel wire of inferior optical fiber is replaced by iron wire or aluminum wire, and the strength is insufficient. , it will bend if you touch it easily, and it will rust and break after a long time.

4. Special attention should be paid to steel when purchasing optical cables. The textured steel strips of high-quality optical cables are of excellent material, and anti-rust measures have been taken on both the front and back sides, while inferior optical cables usually use ordinary iron sheets, which are prone to rust damage.

浙公网安备33018502001191号

浙公网安备33018502001191号