Through the statistical analysis of line faults, the faults caused by factors such as construction, installation, and connection are often much more likely than the faults caused by the defects of the wire and cable itself. Below, Optical Fiber Cable Factory introduces the precautions for cable laying:

1. Cable laying and installation should be carried out by qualified professional units or professionals. Construction and installation that do not meet the requirements of relevant specifications may cause the cable system to fail to operate normally.

2. When laying cables manually, the command and control rhythm should be unified. Every 1.5 to 3 meters, one person should carry the cables on their shoulders, pull them while laying them down, and release them slowly.

3. When mechanically laying cables, a special cable-laying machine is generally used and necessary traction tools are used. The traction force is appropriate and the control is even, so as not to damage the cables.

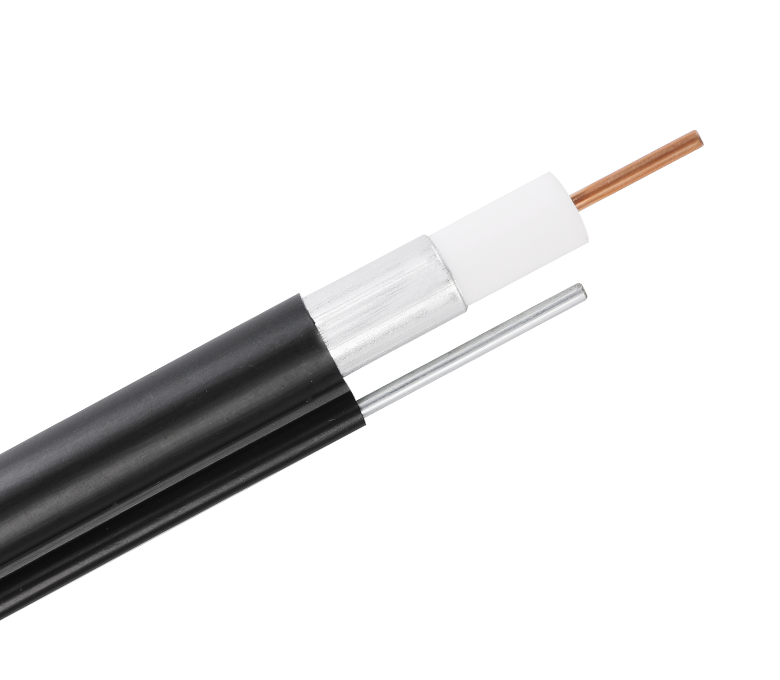

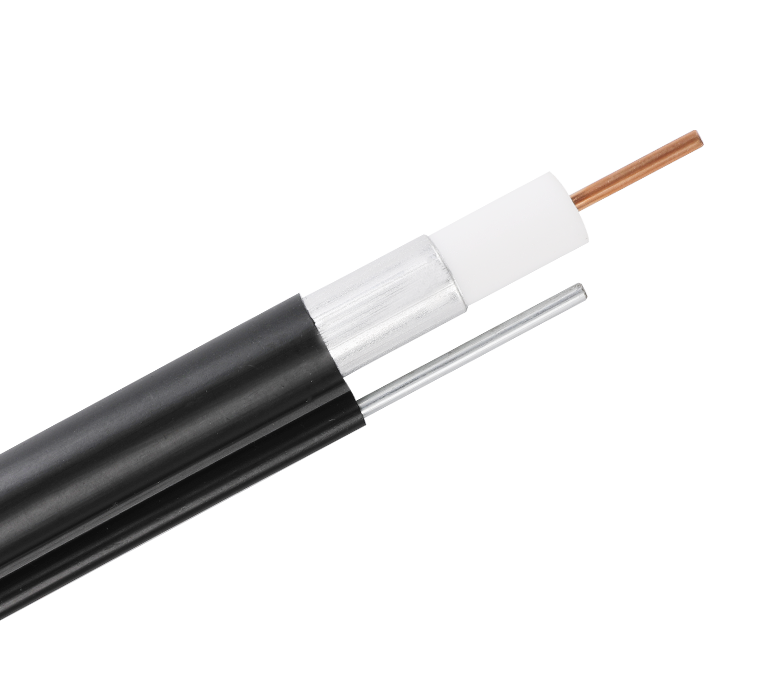

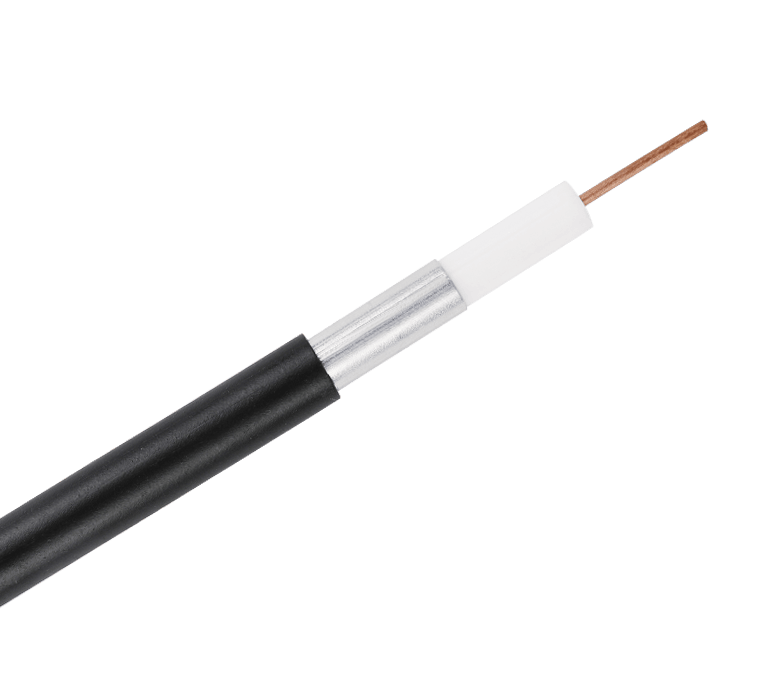

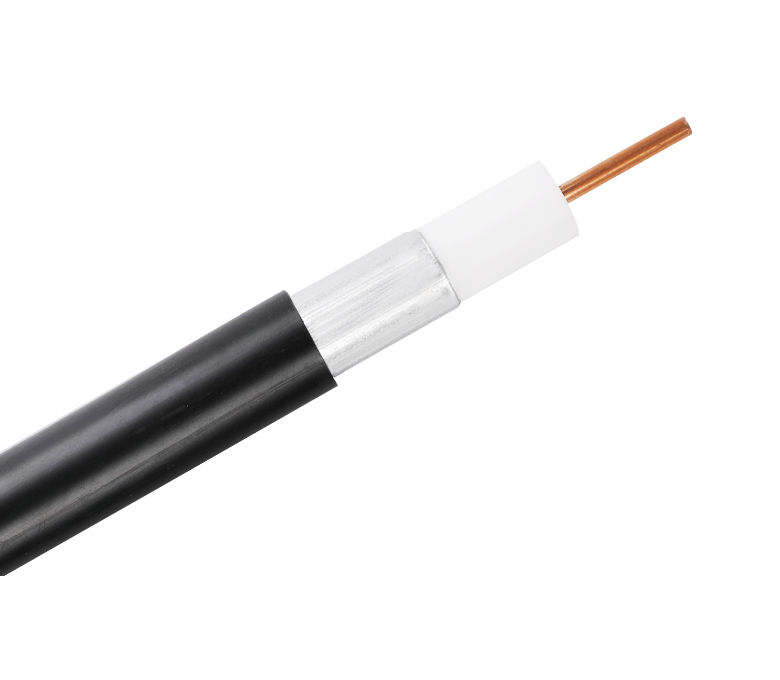

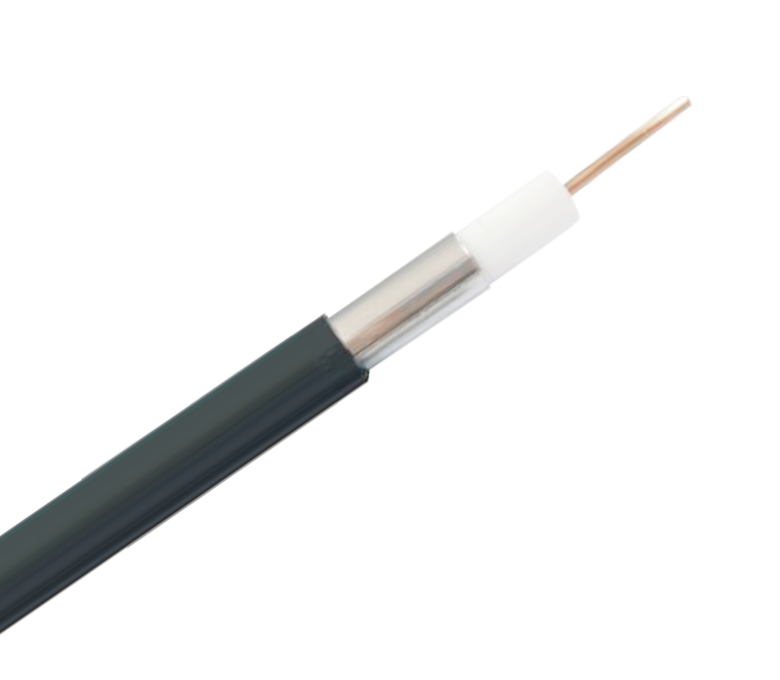

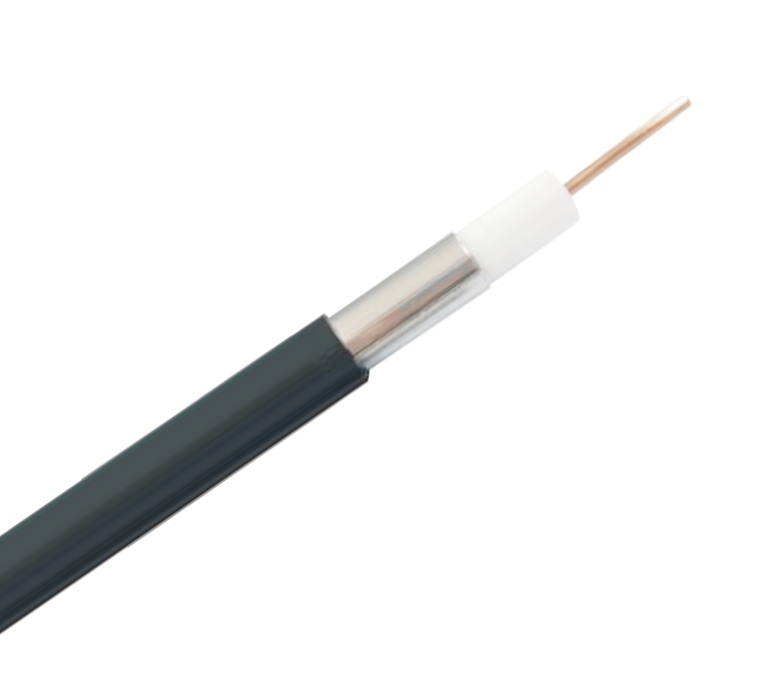

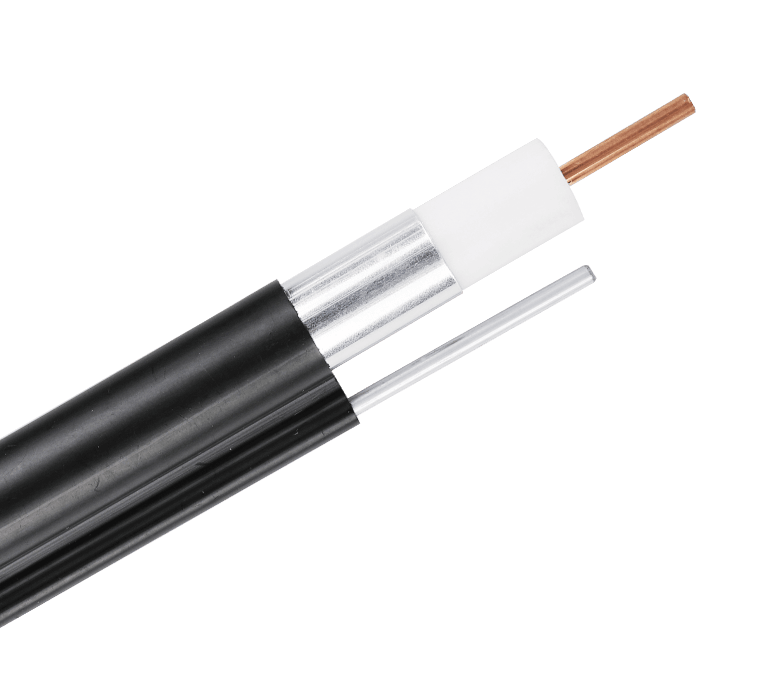

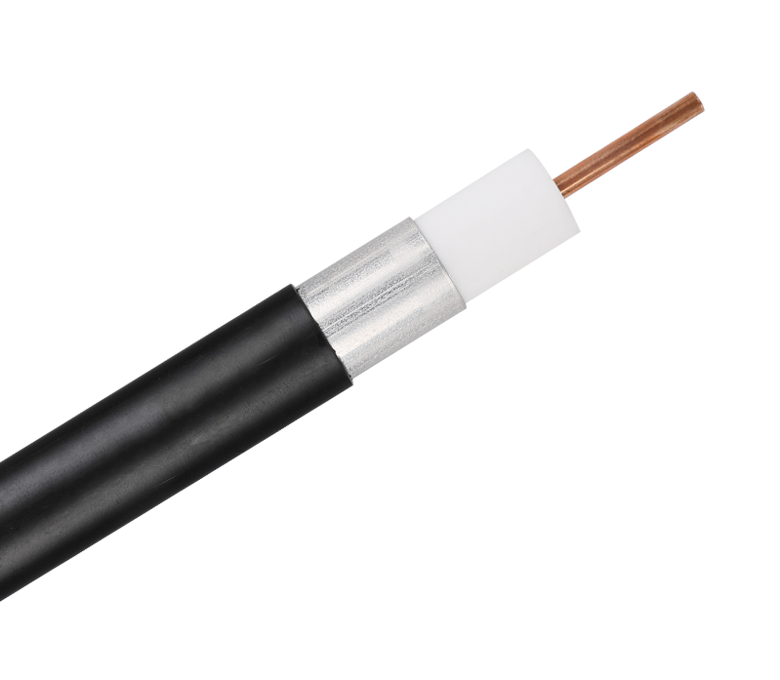

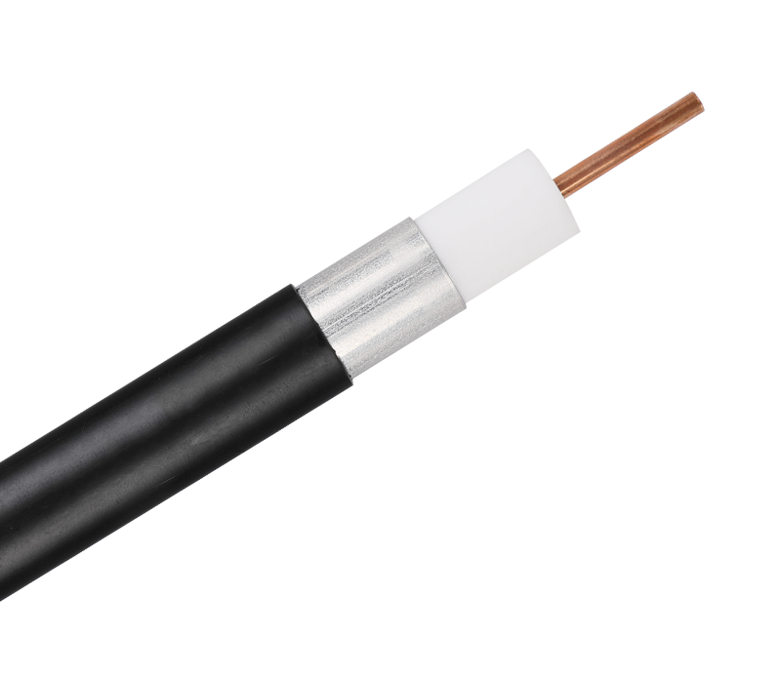

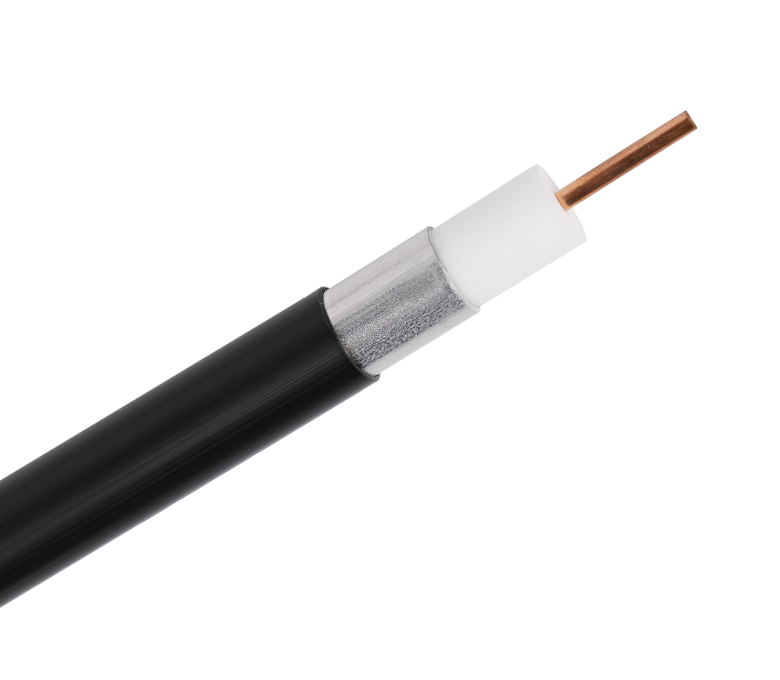

4. Before laying the cable, check the appearance of the cable and whether the head is intact. Pay attention to the rotation direction of the cable reel when laying the cable. Do not flatten or scratch the outer sheath of the cable. Insulation, sheath cracking.

5. When laying, the bending radius of the cable should be larger than the specified value. Before and after the installation of the cable, use a 1000V megger to measure whether the insulation resistance between the conductors of the cable is normal, and make appropriate corrections to the measurement results according to the cable model, length, and ambient temperature. Small size (solid core below 10mm2) Conductor) The cable should also measure whether the conductor is on or off.

浙公网安备33018502001191号

浙公网安备33018502001191号