Rubber-sheathed flexible cables are known for their ability to withstand mechanical stress and wear quite effectively. Their construction and material properties contribute to their durability in demanding environments. Here's how rubber-sheathed cables handle mechanical stress and wear:

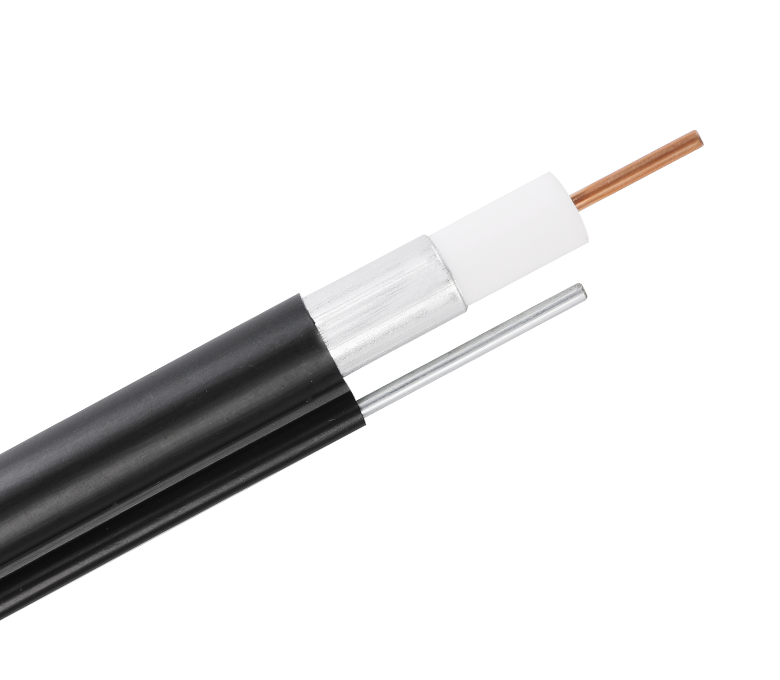

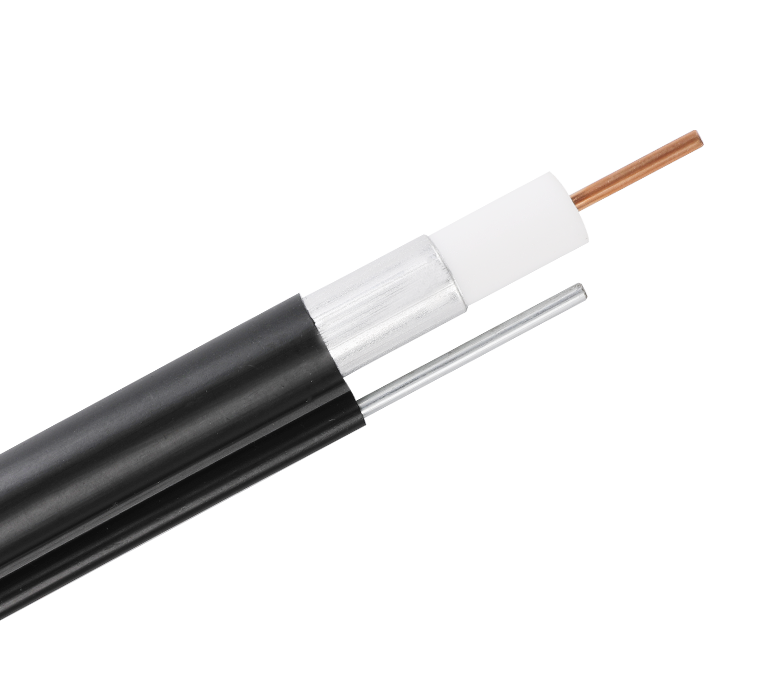

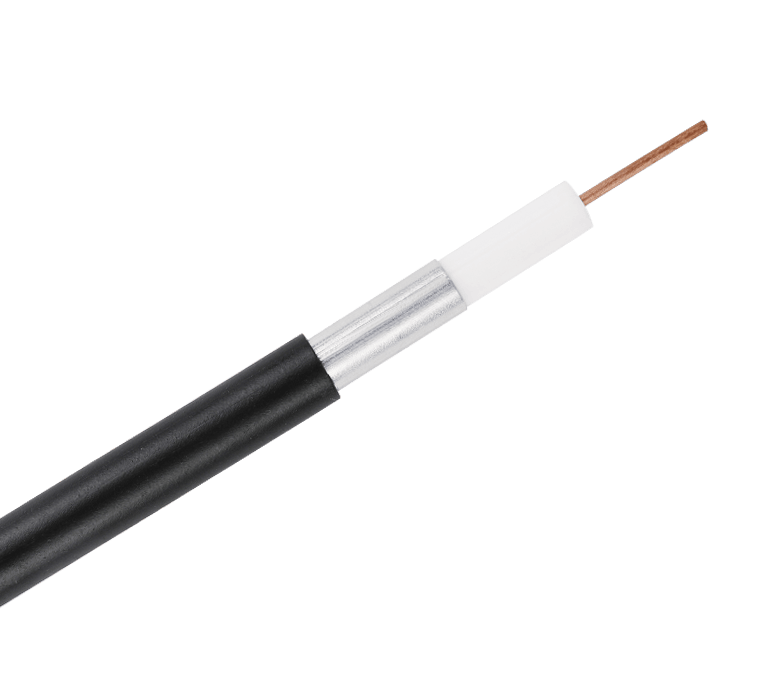

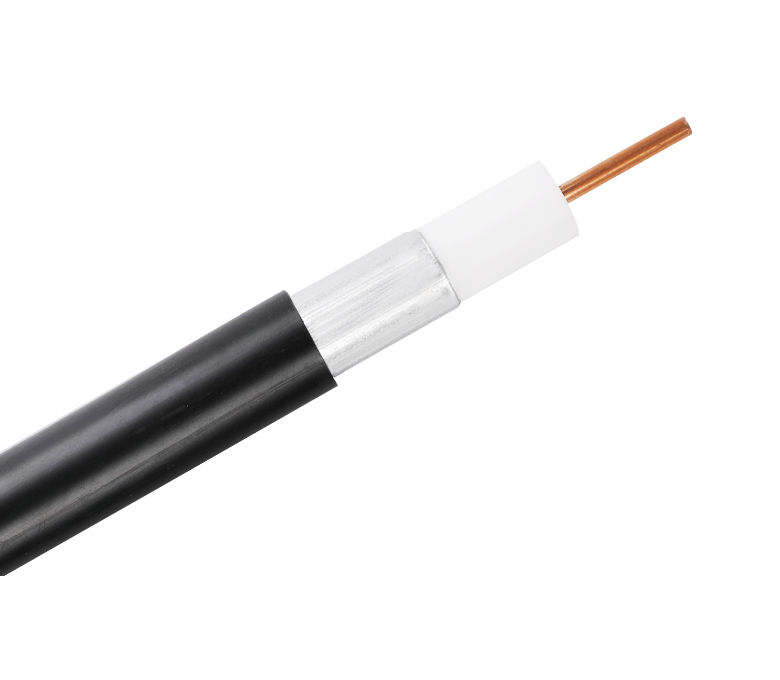

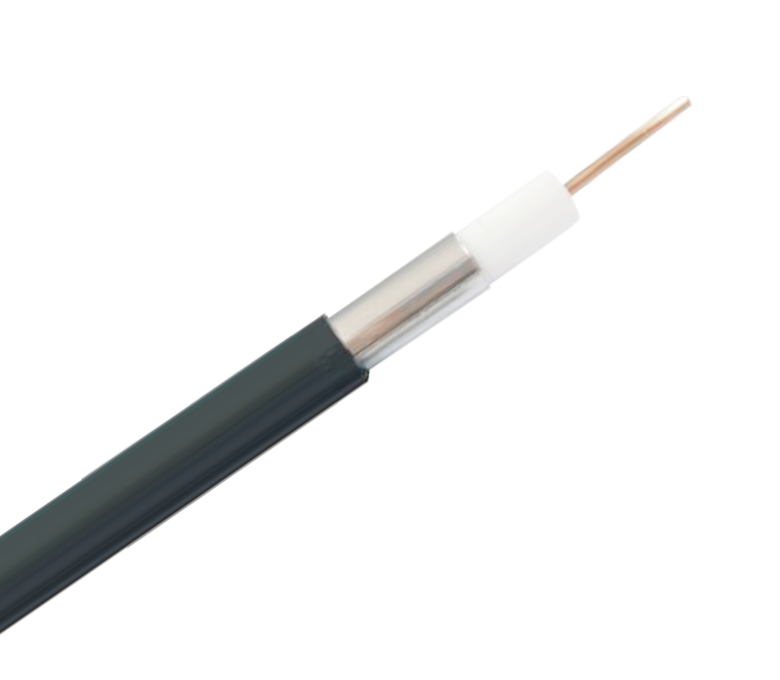

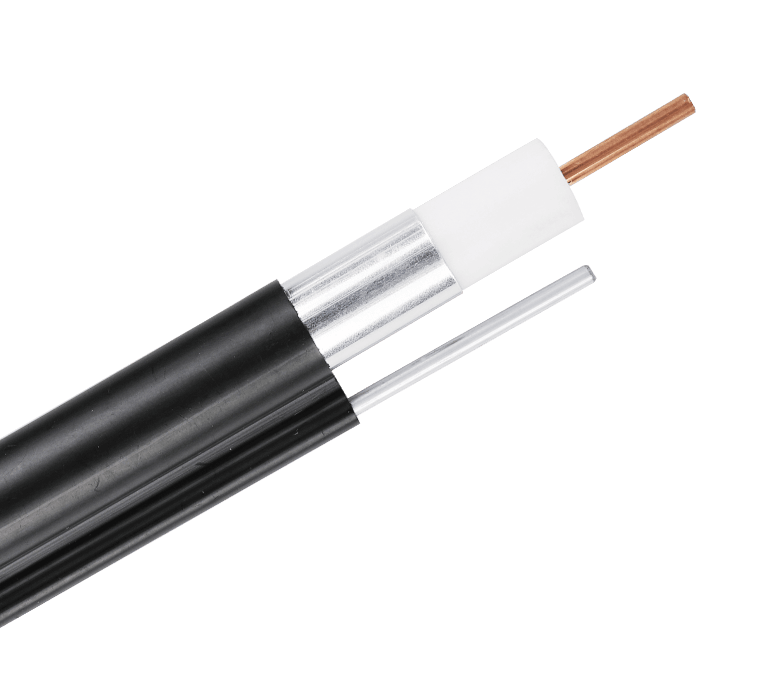

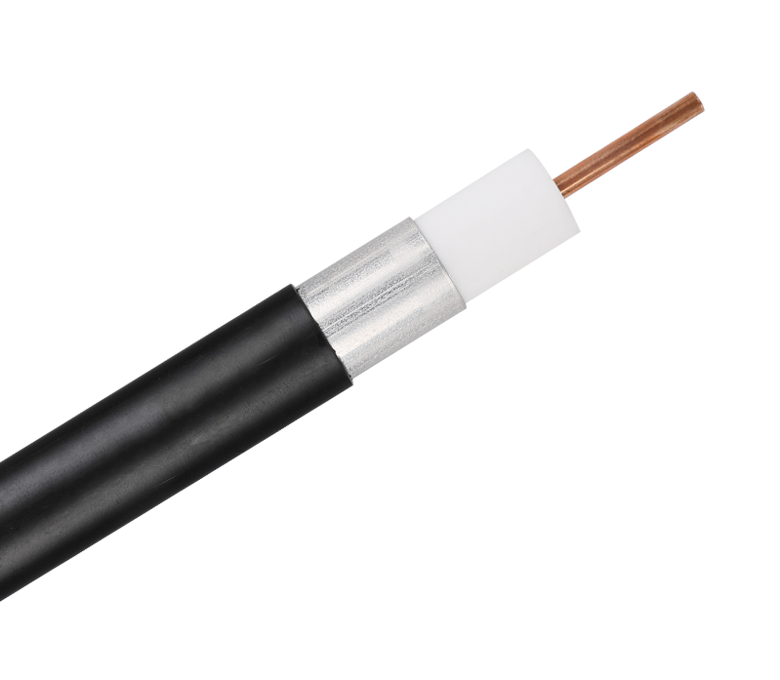

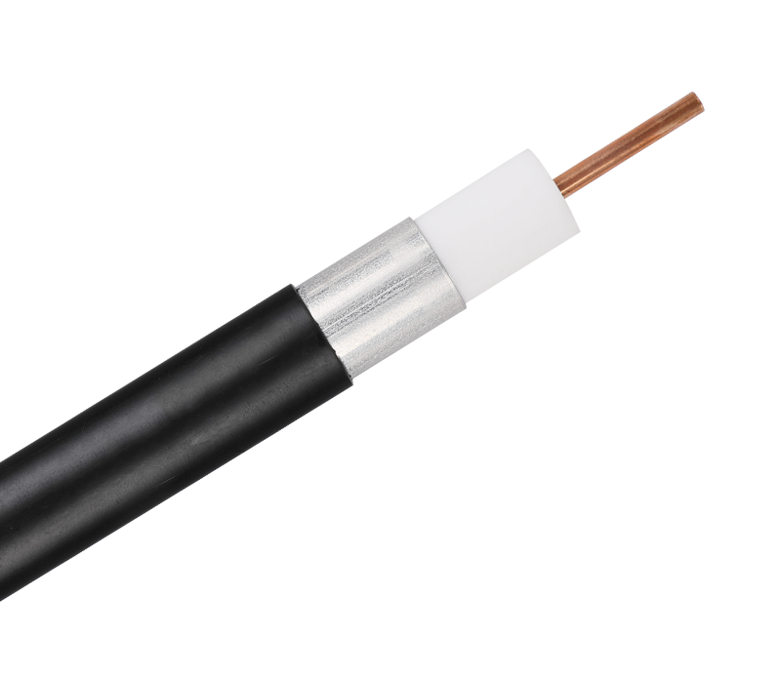

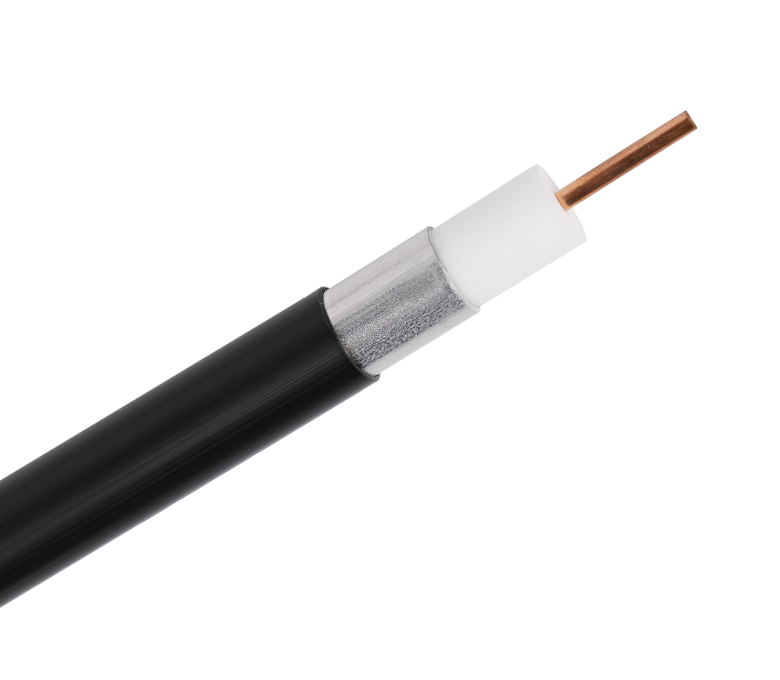

Robust Construction: Rubber-sheathed cables are typically constructed with a strong and durable inner core. This core, composed of copper or aluminum conductors and suitable insulation materials, provides a solid foundation. The outer layer, made of rubber or a rubber-like compound, adds an extra layer of protection and flexibility.

Flexibility: The rubber sheathing of these cables provides flexibility, allowing them to bend and twist without compromising their integrity. This flexibility is crucial in applications where the cable needs to move or change position regularly, such as in portable equipment, industrial machinery with moving parts, and cable harnesses.

Abrasion Resistance: The rubber outer sheath acts as a barrier against abrasion and physical wear. It can protect the internal components from contact with rough surfaces or other materials that might cause friction. This resistance to abrasion is particularly important in applications where cables are exposed to constant movement or contact with abrasive materials.

Impact Resistance: Rubber-sheathed cables can withstand moderate impacts without sustaining damage. Their rugged construction and flexibility help absorb and distribute the force of impacts, reducing the risk of damage to the cable's core and insulation.

Longevity: Thanks to their robust construction and resistance to mechanical stress and wear, rubber-sheathed cables often have a longer service life compared to cables with less durable sheathing materials like PVC. This longevity can result in cost savings over time as the cables require less frequent replacement.

Maintenance and Reliability: The ability of these cables to handle mechanical stress and wear without degradation contributes to the overall reliability of the electrical system. Less frequent maintenance or replacement means less downtime and reduced maintenance costs.

It's important to note that while rubber-sheathed cables are durable and can withstand mechanical stress and wear effectively, their performance also depends on factors such as proper installation, handling, and the specific environmental conditions in which they are used. Regular inspections and maintenance can help ensure the continued reliability of these cables in industrial, commercial, and residential applications.

浙公网安备33018502001191号

浙公网安备33018502001191号