Control distribution cables are designed and engineered to address excessive voltage stages and heavy modern hundreds via numerous key capabilities:

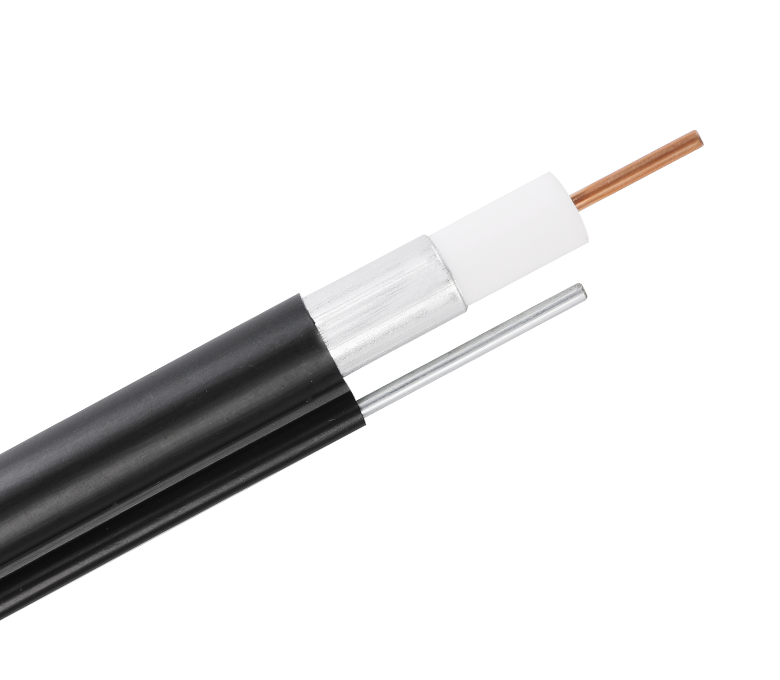

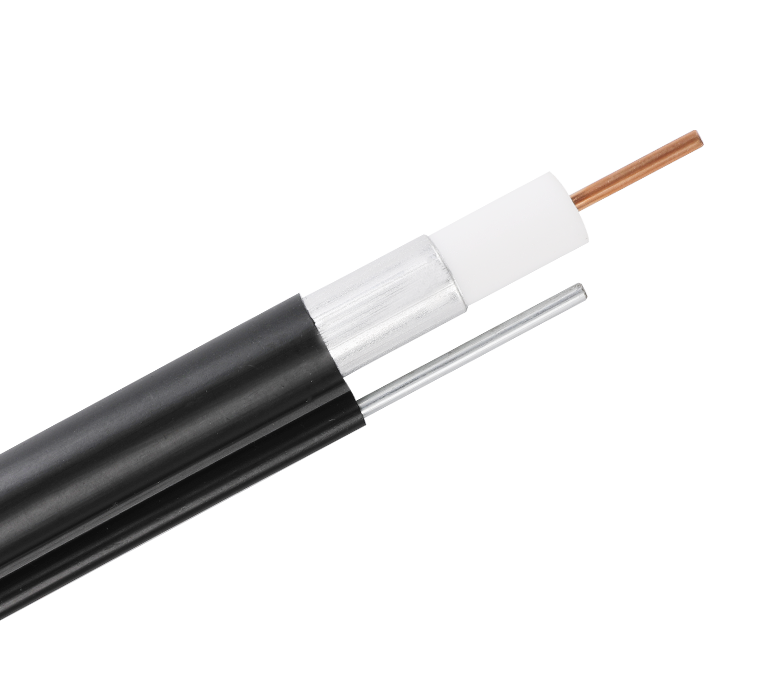

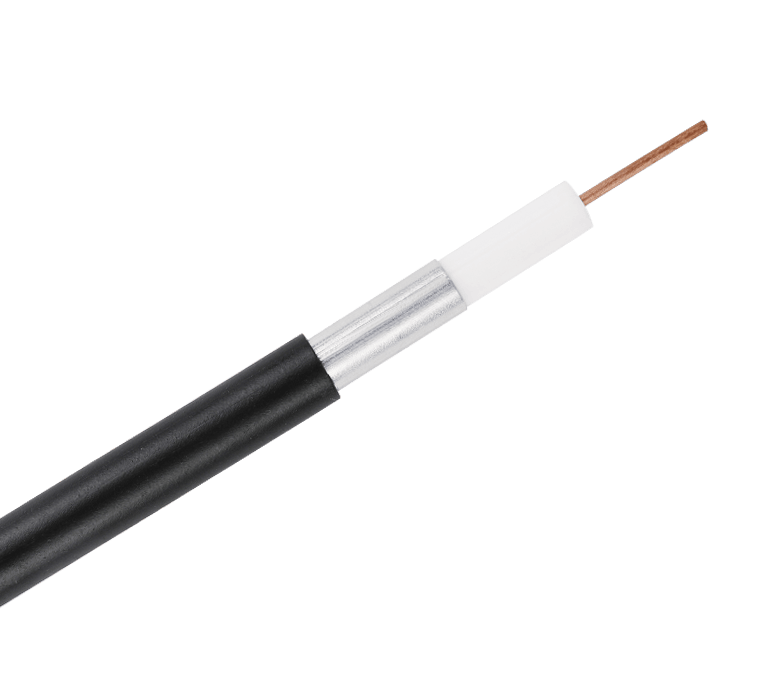

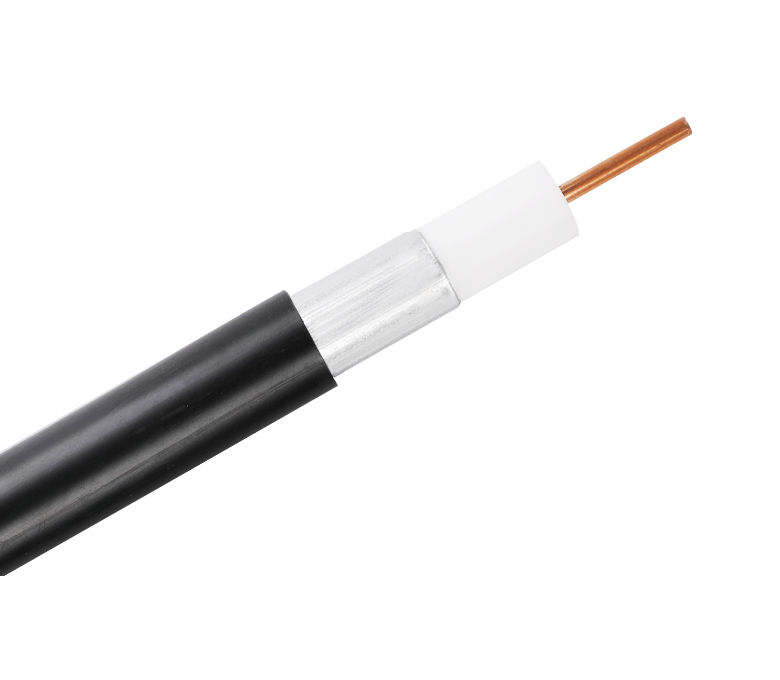

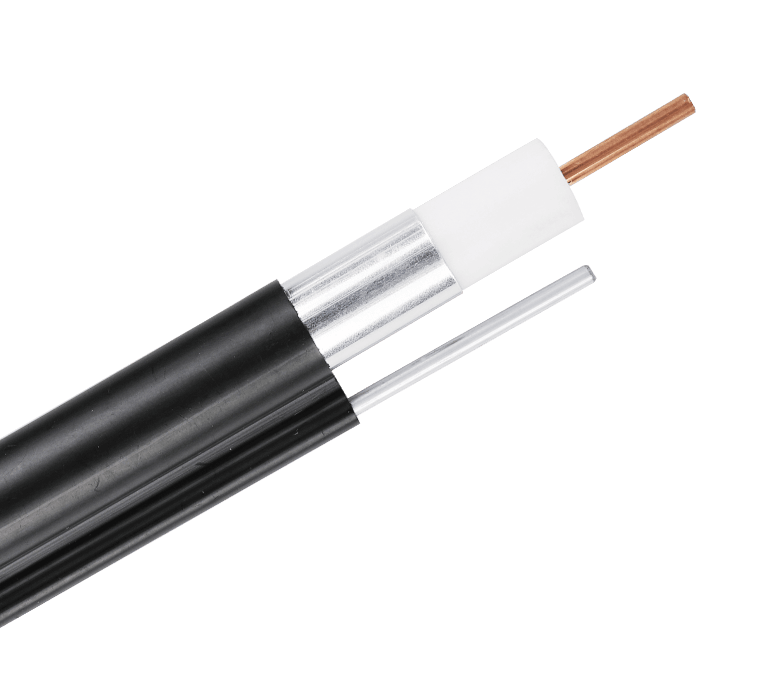

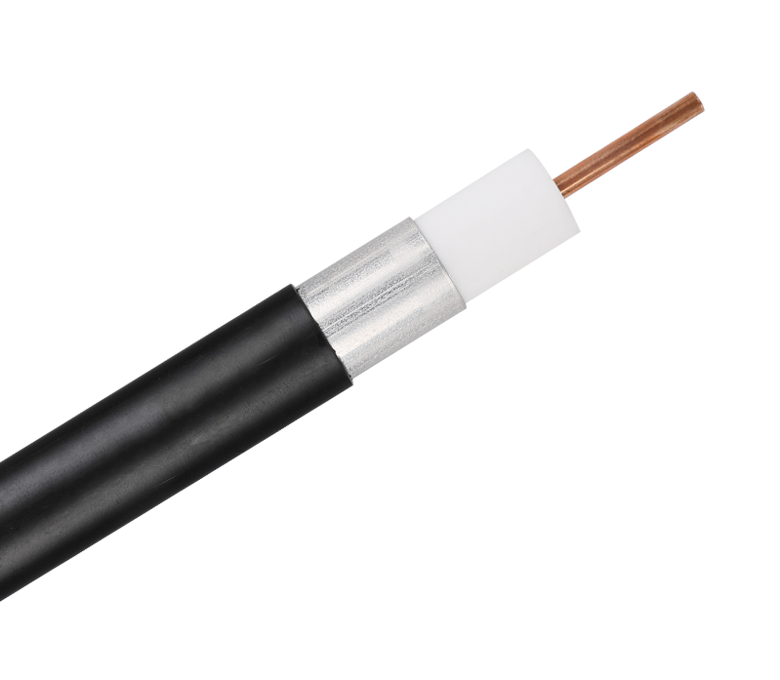

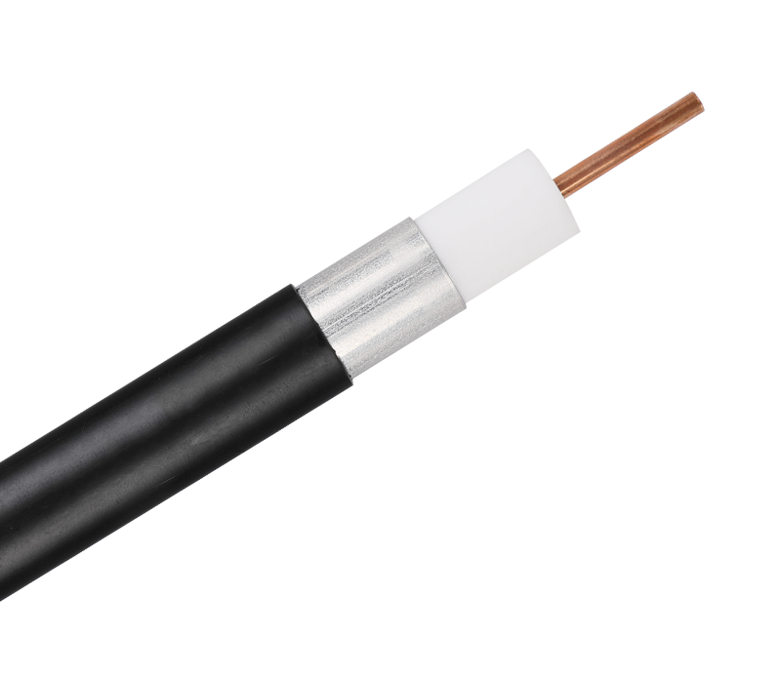

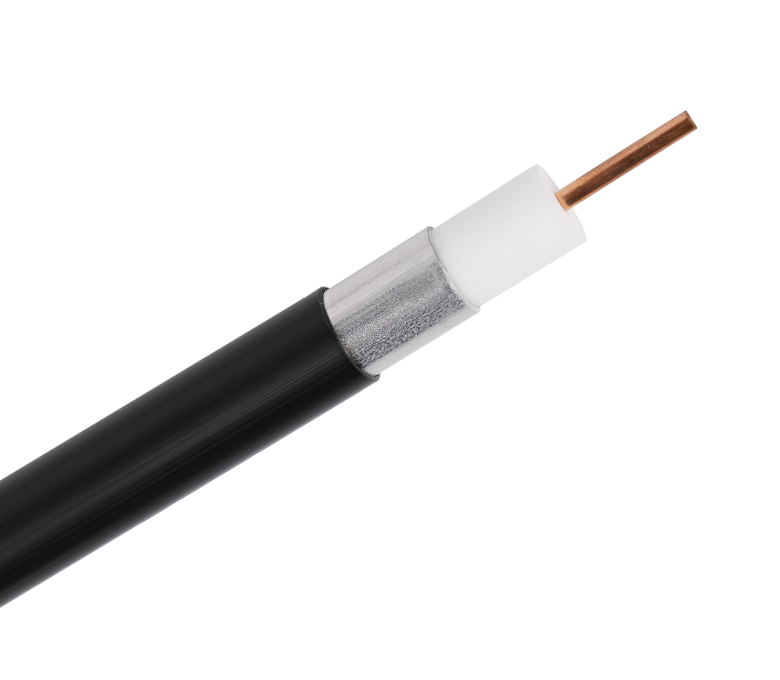

1. Robust Construction: These cables are usually constructed with wonderful substances together with copper or aluminum conductors which have superb electric conductivity. The conductors are frequently stranded to enhance flexibility and sturdiness.

2. Insulation: Control distribution cables are insulated with specialized substances that have excessive dielectric power and might withstand high voltage levels with out breaking down or inflicting leaks. Common insulation materials consist of PVC (Polyvinyl Chloride), XLPE (Cross-Linked Polyethylene), or EPR (Ethylene Propylene Rubber).

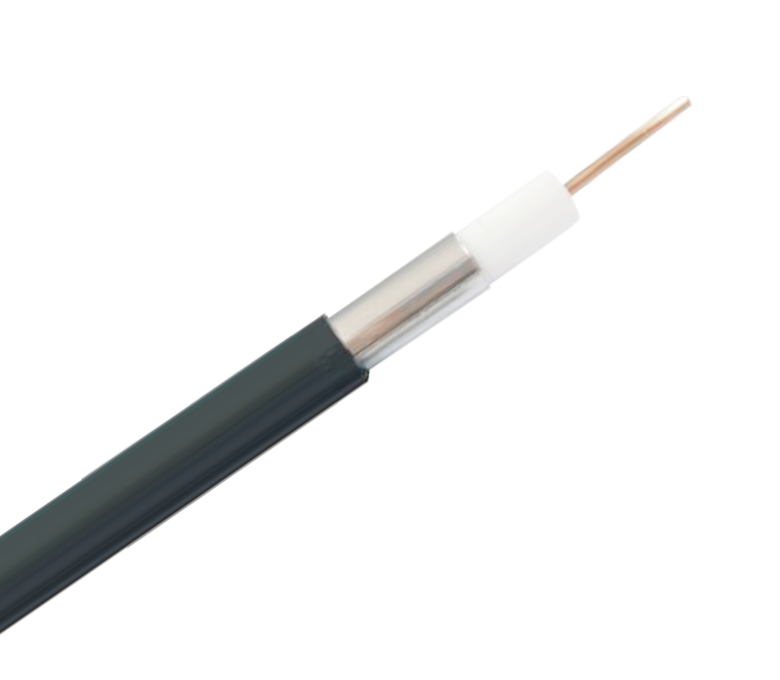

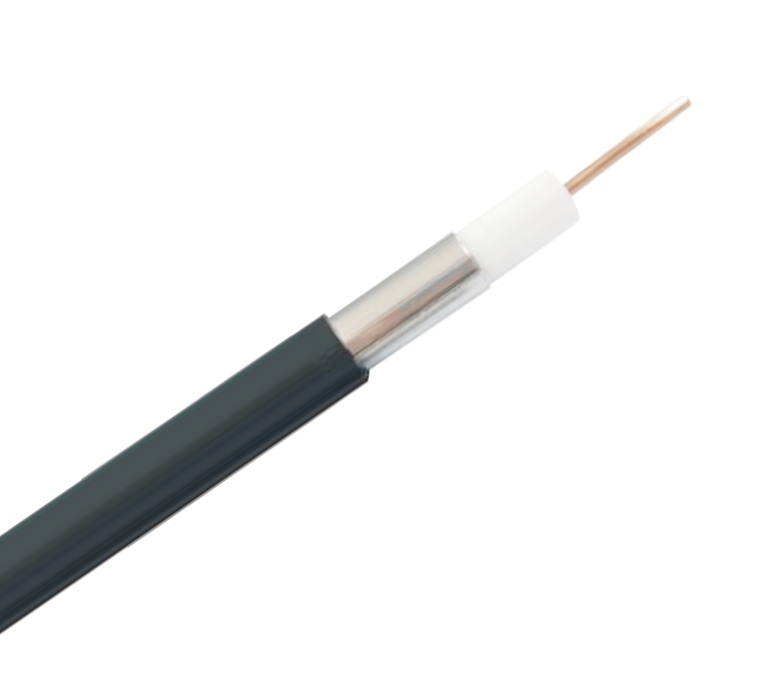

3. Shielding: To protect in opposition to outside interferences or electromagnetic interference (EMI), control distribution cables are often equipped with protecting layers. These protective layers, consisting of metal foils or displays, assist to limit signal degradation and hold a stable strength glide.

4. Size and Gauge: Control distribution cables are to be had in diverse sizes and gauges to accommodate extraordinary voltage and modern-day requirements. Thicker cables with large gauge sizes have a better ampacity, permitting them to address extra present day without overheating.

5. Safety Measures: Control distribution cables are designed to meet protection requirements and regulations. They regularly have extra capabilities like flame-retardant or hearth-resistant residences to ensure the maximum protection in disturbing commercial environments.

By incorporating those design elements, manage distribution cables can efficaciously take care of high voltage ranges and heavy present day loads even as maintaining dependable energy transmission and minimizing the threat of electrical dangers.

浙公网安备33018502001191号

浙公网安备33018502001191号