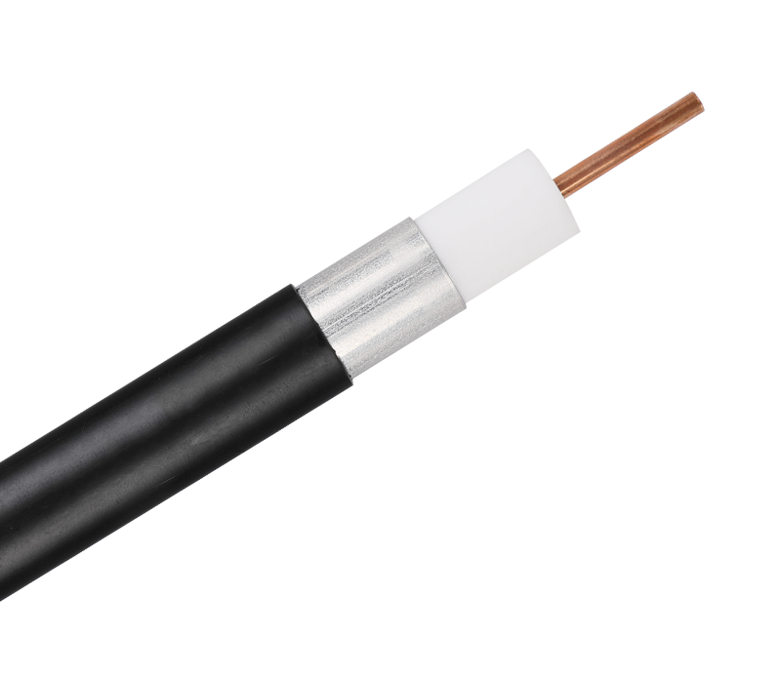

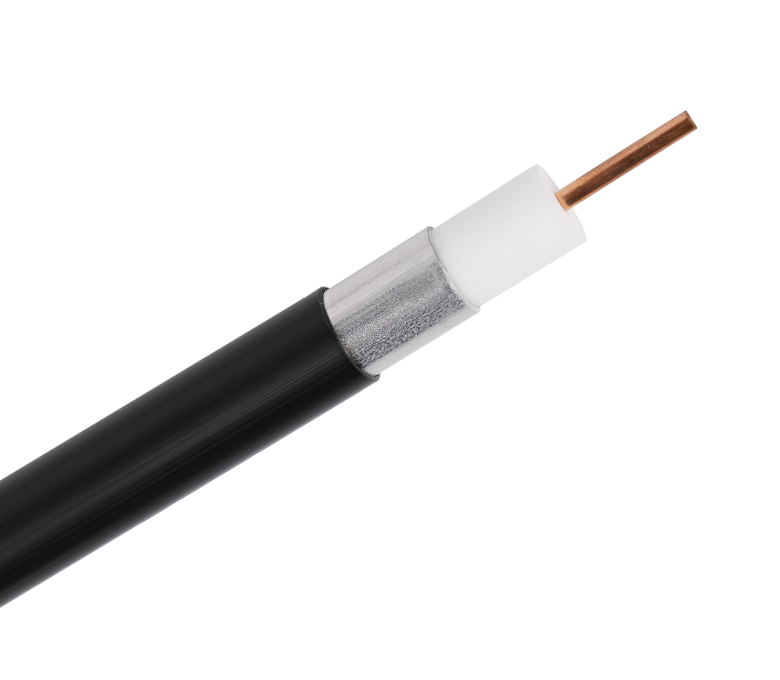

75 Ohm Trunk Cable Suppliers explains how to handle wire splice:

1. When connecting the wires, make sure that the parts of the connectors are very firm. Many electricians may simply twist the wire splice together, which is not the most standard way to do it. The requirements of the connector are also very clear. First of all, the resistance should not be greater than that of the wire, otherwise it will affect the safety of electricity use and cause overheating.

2. At the same time, to meet the requirements of strength, the joint part should be done well, and the insulation should not be less than the main line. Moreover, it is necessary to increase its corrosion resistance to ensure a longer service life and no circuit failure.

3. The head of the connector should be reserved for a certain length. Generally speaking, it will protrude 15 cm, and then remove the remaining part of the insulation. Next, distinguish the color of the wire. Generally speaking, the live wire is represented by red, and the neutral wire is blue. . If it is connected to a dual-control switch, there are many live wires with different colors, which need to be effectively distinguished by an electric pen. The joints are insulated, preferably by hot tin.

4. The joint connection method, some are single-core and single-strand, and the diameter is the same, which can be wound around each other several times, and finally cut off the excess wire ends. If they are of different diameters, wrap the thin one around the thicker one, and then wrap it five or six times. Pull the thick thread back, press it down, and finally trim off the excess thread.

浙公网安备33018502001191号

浙公网安备33018502001191号